Stainless steel is a versatile and durable material that has been used in various applications, ranging from household items to industrial machinery. It is well known for its resistance to corrosion and staining, making it a popular choice for manufacturing and construction. However, with the increasing demand for a more aesthetically pleasing finish, black oxide coating has become a popular option for stainless steel. This type of coating not only provides a sleek and stylish appearance, but it also enhances the durability and longevity of the material. In this article, we will explore the benefits of black oxide coating on stainless steel and why it is an ideal choice for various applications.

What is Black Oxide Coating on Stainless Steel?

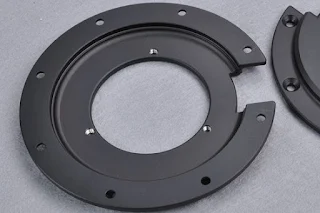

Black oxide coating, also known as blackening or gun bluing, is a process of converting the surface of stainless steel into a black, protective finish. This coating is achieved by immersing the stainless steel in a solution of black oxide or by applying a black oxide solution directly to the surface of the metal. The black oxide coating forms a layer of iron oxide, which acts as a barrier to protect the underlying stainless steel from corrosion and oxidation. The resulting finish is not only stylish, but it also enhances the durability of the material, making it an ideal choice for various applications.

Benefits of Black Oxide Coating on Stainless Steel

There are several benefits to using black oxide coating on stainless steel. Some of the key benefits include:

- Enhanced Durability: The black oxide coating provides an additional layer of protection against corrosion, rust, and oxidation. This makes the material more durable and less prone to wear and tear, extending its lifespan.

- Aesthetic Appeal: The black oxide finish provides a sleek and stylish appearance that is perfect for various applications. It is also ideal for applications where a low-reflective surface is required, as it reduces glare and reflections.

- Improved Adhesion: The black oxide coating enhances the adhesion of other coatings, such as paints, primers, and other finishes. This allows for the creation of multi-layer coatings for enhanced protection and appearance.

- Increased Lubricity: The black oxide coating provides a smooth and even surface, which enhances the lubricity of the material. This is ideal for applications where sliding and moving parts are required, as it reduces friction and wear.

- Low Maintenance: The black oxide coating is low maintenance and does not require any special cleaning or care. This makes it an ideal choice for various applications where maintenance and upkeep are a concern.

Applications of Black Oxide Coated Stainless Steel

Black oxide coated stainless steel is used in a variety of applications, including:

- Industrial Machinery: Black oxide coated stainless steel is used in various types of industrial machinery, such as conveyors, pumps, valves, and gears. It provides a durable and long-lasting finish that is resistant to corrosion and wear.

- Medical Equipment: Black oxide coated stainless steel is used in the manufacture of various types of medical equipment, such as surgical instruments, implantable devices, and diagnostic equipment. It provides a safe and durable surface that is resistant to corrosion and oxidation.

- Automotive Parts: Black oxide coated stainless steel is used in the manufacture of various types of automotive parts, such as engine components, drive shafts, and suspension parts. It provides a durable and long-lasting finish that is resistant to corrosion and wear.

Post a Comment for "The Long-Lasting Durability of Black Oxide Coating Stainless Steel"